| Sector: | Defence |

| Customer: | Lucas Aerospace, now Collins Aerospace |

| Duration of supply: | 3 years |

| Contract value: | £2.4 million |

| Investment: | £850k |

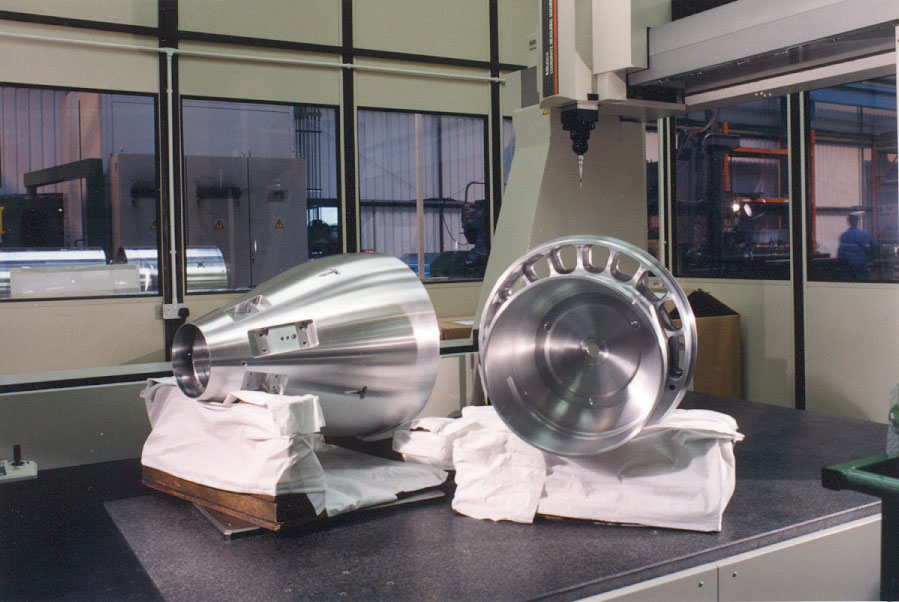

CNC investment

The company’s investment included the procurement of a CNC twin pallet horizontal machining centre, a CNC vertical turning machine and a CMM, coordinate measuring machine, in a temperature-controlled environment. NEC was processing several operations on these parts to assist our customer in getting back onto the delivery program. Lucas Aerospace could not produce these parts to specification with their existing plant and was looking at the feasibility of investing in new facilities. NEC suggested that they set up a cell for the manufacture of these parts; this would enable the customer to solve their problems without capital expenditure.After producing a detailed cost model for the cell and identifying the correct machinery, equipment, and processes wpresented our proposal to the customer. A contract was negotiated which justified our investment and gave the customer guaranteed security of supply.

TESTIMONIAL:

NEC brought deliveries back onto program and produced what the customer described as “the best hulls ever”.