Core Capabilities

- 9 axis mill turn

- Milling up to a 1m3

- Turning up to 2m long x 700mm dia.

- Advanced manufacturing inc.

- rotary 4th axis milling with automatic vice and robot loading/unloading

- turning with Y axis, driven tooling and auto bar feeder

- Fabrication and welding

- Water Jet Cutting

- ISO Certified processes and systems

- Assembly & Test

- Design for Manufacture

- Product Development

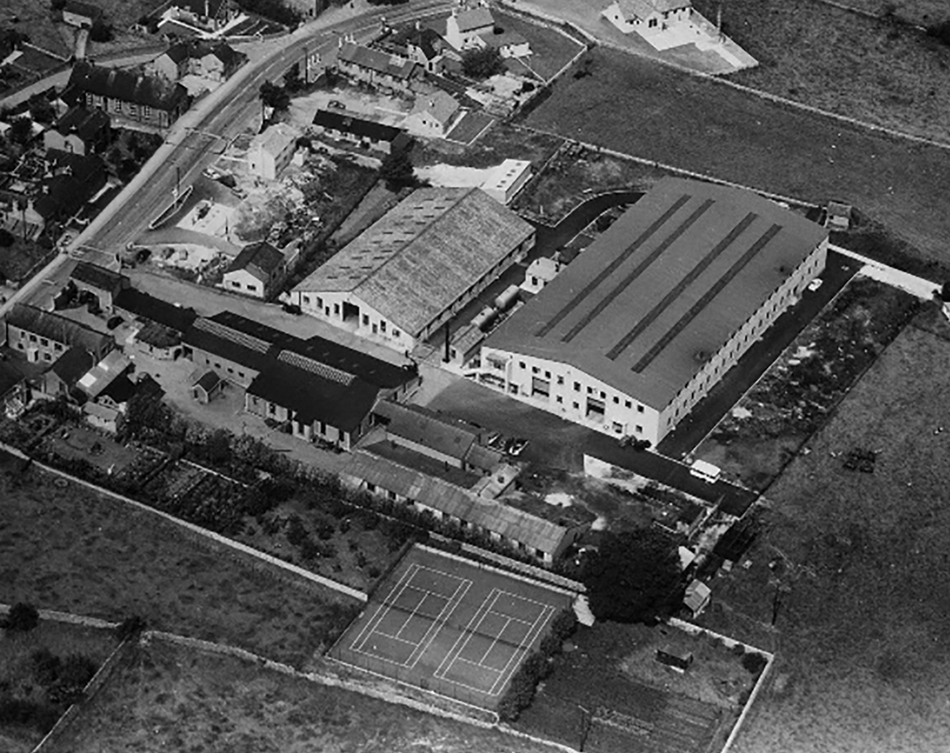

- Secure Site